Shina Mechanical Equipment Co., Ltd!

Vibration mill series MZ200

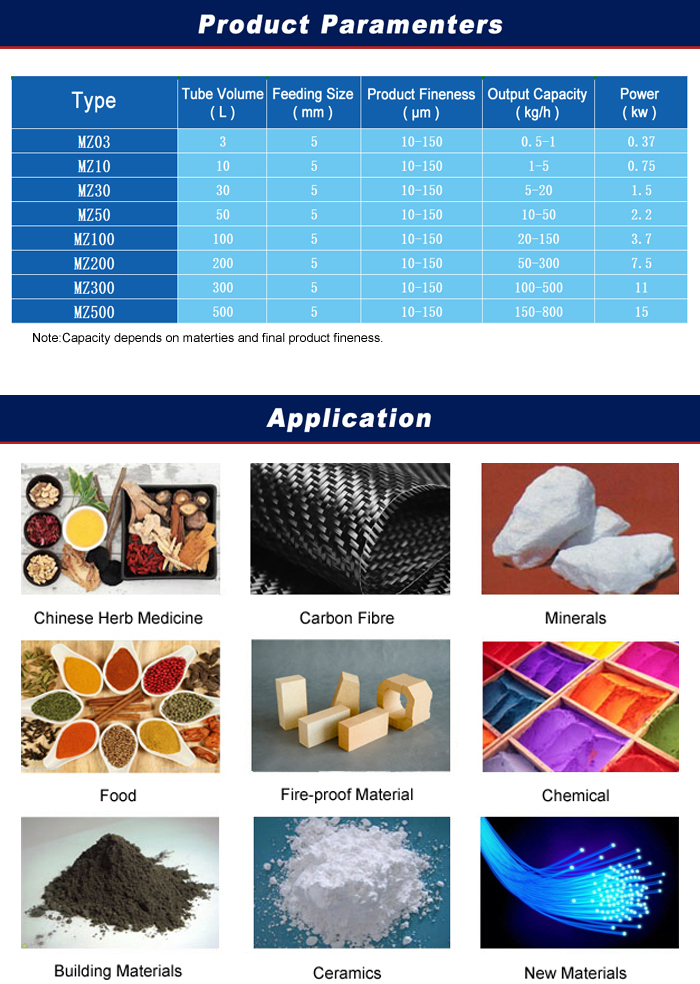

- Suitable for hard and soft materials with Mohs' hardness<7.

- Compared to ball mill, air-stream mill and impacting mill, it has low investment cost, low

energy consumption, simple flow, high efficiency andreasonable price.

- Particle size can be changed by adjusting quantities of feed materials, amplitudeof vibration and

grinding media' s grades. To form series connection with classifier to get products with narrower

size distribution.

- Grinding Medias and scale-board are made of high manganese steel, high cadmium steel

stainless steel, AL2O3, ZrO2 and quartz materials. Wear resistance and no pollution.

- To crush heat- sensitive and low melting point materials by the method of water cooling or strong

refrigeration system.

- To use single machine to change products' nature and finish its mixture during crushing.

- According to materials' nature, to adopt dry mill, wet mill, continuous mill or intermittent mill.

- According to GMP, used in dugs, herbal medicine, food, health-care. Or research institutes and

Lab.

- To adopt air spring or rubber spring instead of hard spring. Long life, good vibration absorbing

results and low noises.

![]()

Tel.: 0086 158 5326 1107

Email: sales@qdshina.com

Address: 207 Shenzhen South Road, Laixi, Qingdao city, China.

Tiktok

国内销售部:0532-88413877

国际销售部:15853261107

技术部:15853227399

售后:15725258766

邮箱:sales@qdshina.com

地址:青岛莱西市深圳南路207号